We design, manufacture and supply rainscreen cladding from our 45,000ft2 state-of-the-art facility in County Durham, which has capacity to handle large schemes with the latest manufacturing and fabrication machinery.

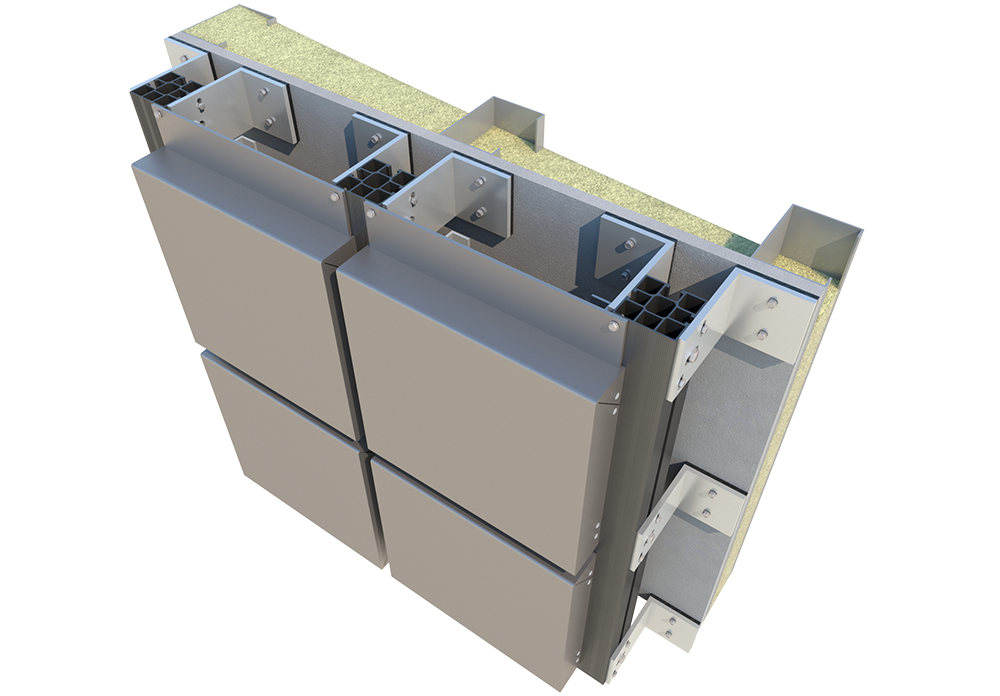

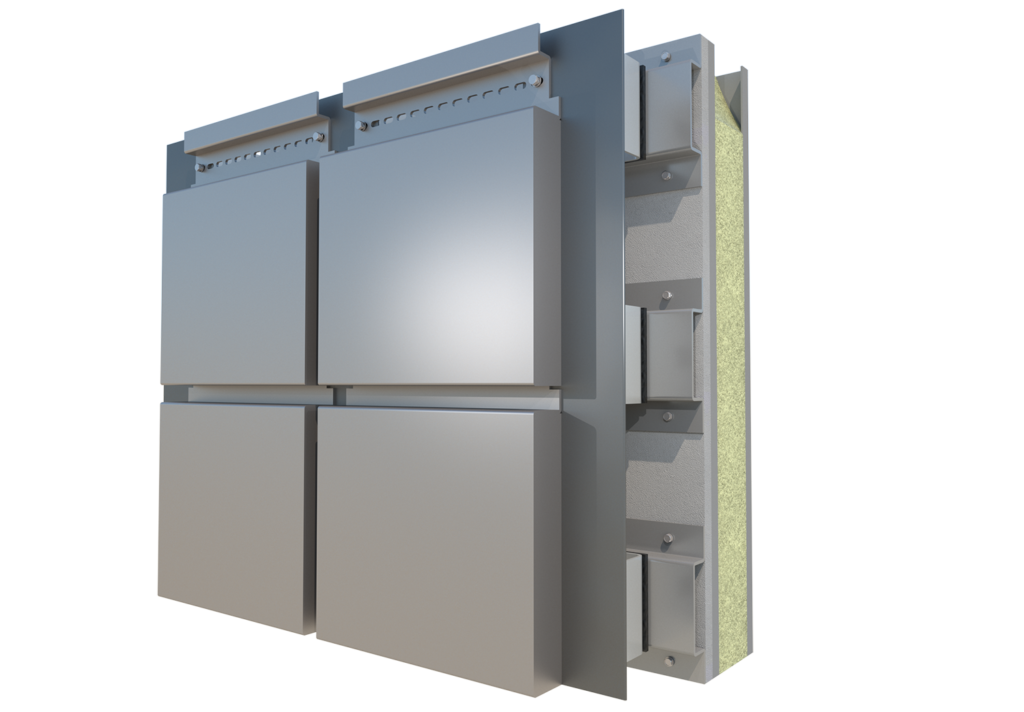

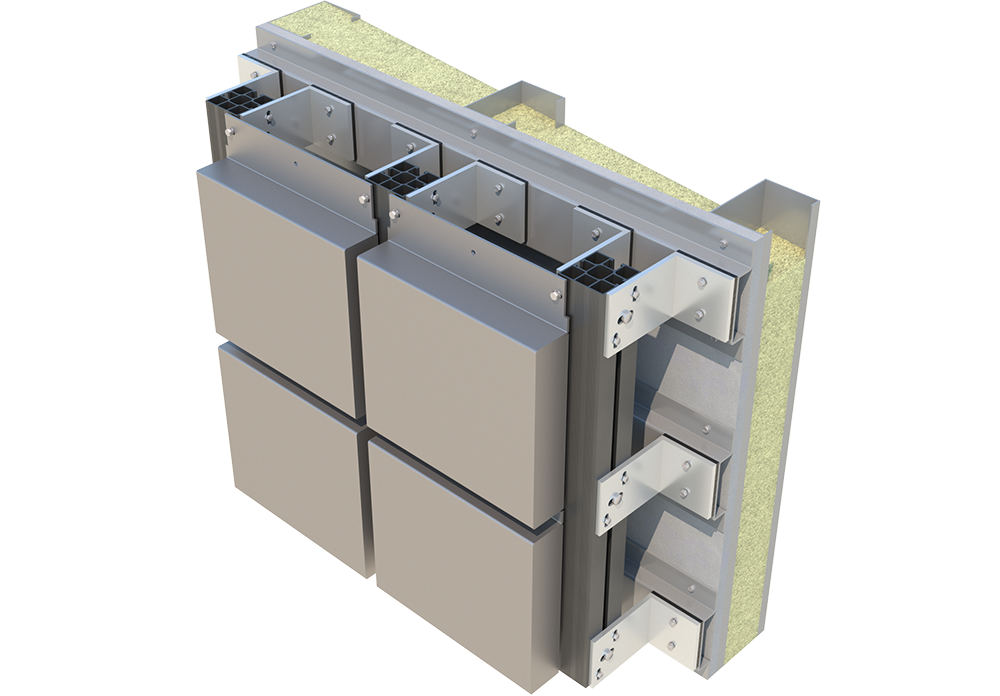

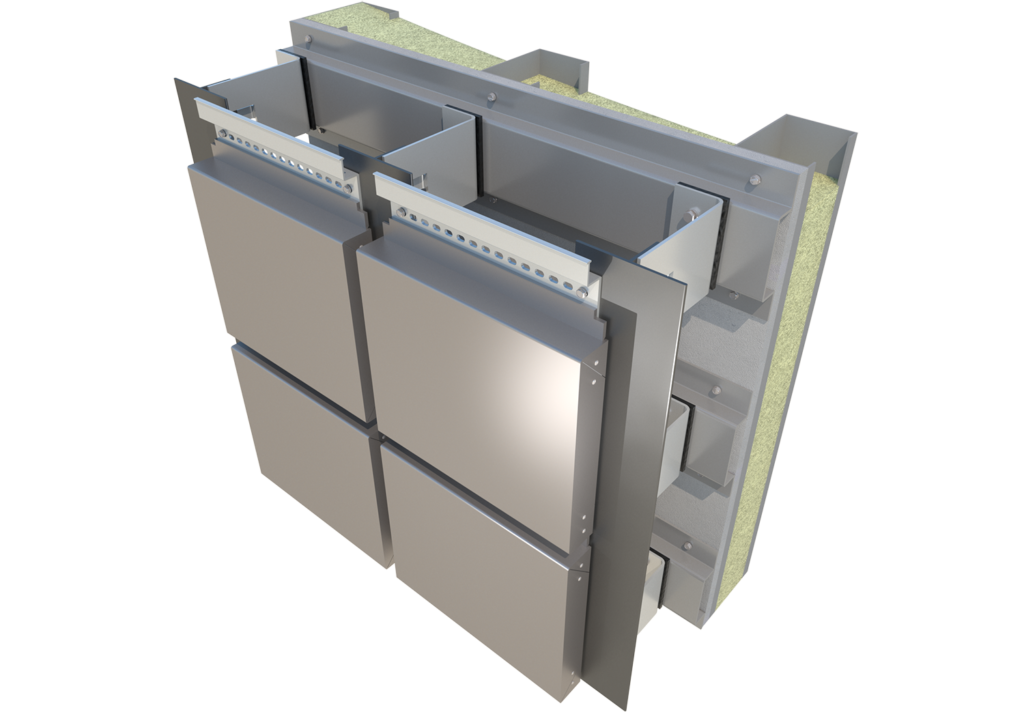

The CWCT tested Matrix SFCM rainscreen system is based on the use of pre-coated metal composite materials such as ACM, ZCM CCM etc. Panels are manufactured on a flatbed CNC machine which offers high tolerances and very sharp folds.

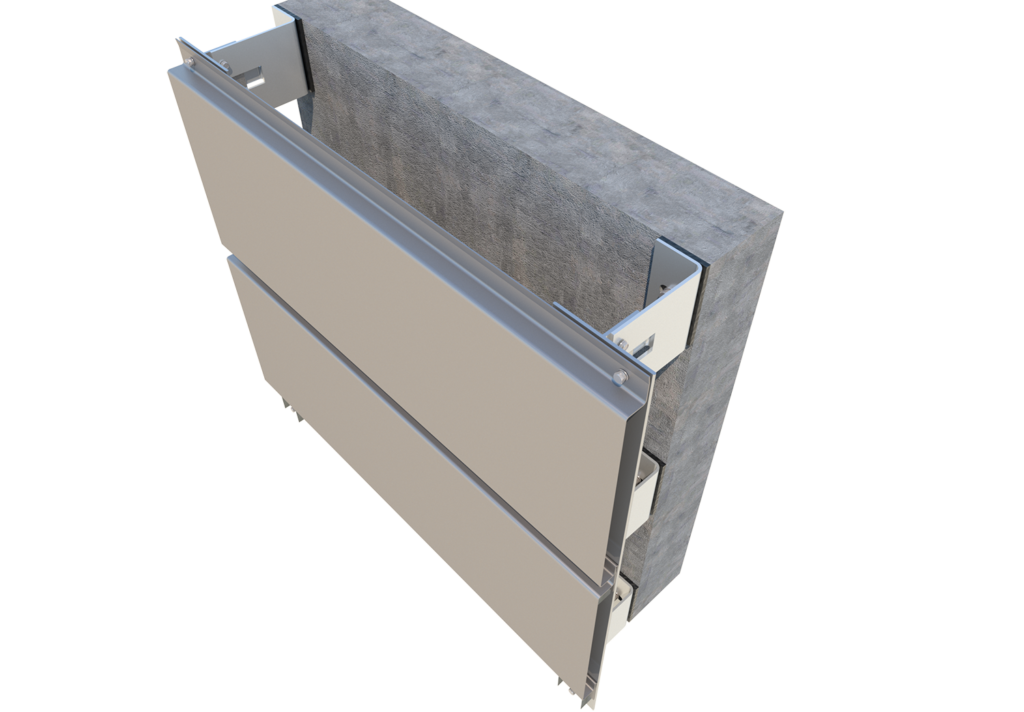

This rainscreen system is available in a range of finishes and thicknesses; with fire rated cores the Matrix SFCM rainscreen system is ideal for providing a flat panel in large format modular grids. The most suitable type of secondary support structure is generally dictated by the panel orientation along with the ability to incorporate thermal and floor movements where required.

Matrix SFCM rainscreen systems are available in a range of materials with special features including pressings and louvers. These can be manufactured to match panels.

System benefits include:

- Fully tested and accredited rainscreen system to CWCT standards

- Quick and easy installation to backing structure

- Wide colour and finish choice, including PPC and anodised

- Panel lengths available up to 6m

Technical Details:

Visible Material Face (Outer Skin):

Aluminium Composite Material – classified A2 rated

Finish:

PSP offer many different finishes through the use of various suppliers

Fixing:

Secret / discreet fix method

Joints:

Nominal 20mm vertical and horizontal joints

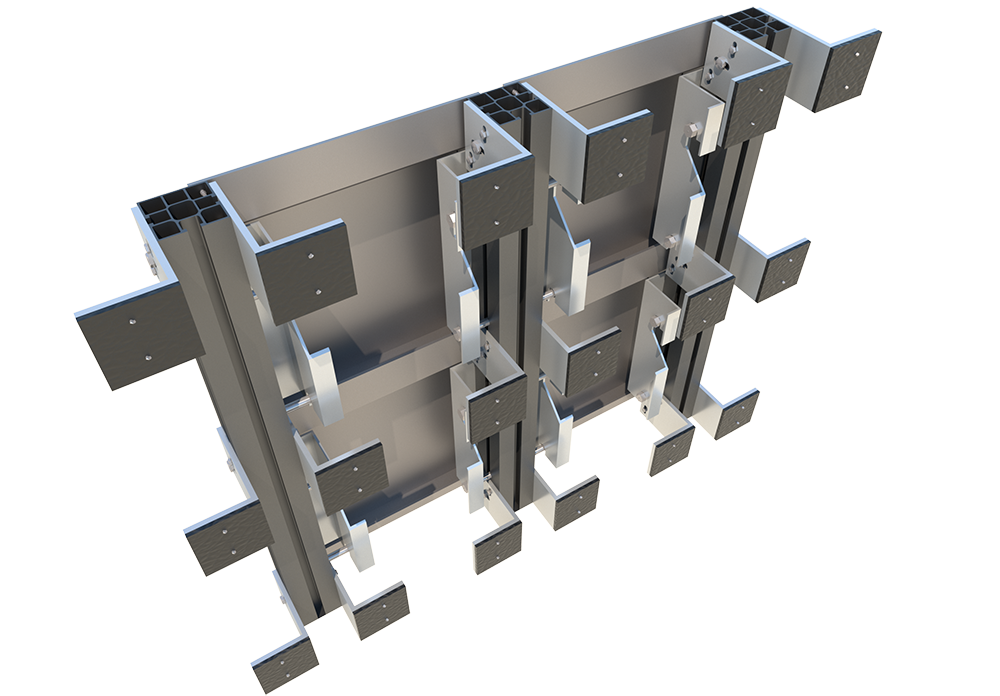

Support:

PSP M60 Hook on Mullion

Ancillaries:

Fixings to enable connection between cleat and mullion and panel to mullion by PSP. Main fix from bracket to structure will be done by others

BROCHURE DOWNLOAD

More information about

Matrix SFC & SFCM Rainscreen

Cladding can be found here

Alternatively, for inspiration

why not check out our online

Project Gallery

PSP Hook on System:

The Hook on system can be used for any panel orientation where thermal and floor movement is occurring. The spring loaded offset head dowels allow for these to be inserted anywhere on the rail and do not have to be slid down the whole length. The spring itself will ensure the dowels do not fall to the bottom.

PSP are able to offer a range of support grids to suit most cavity build ups. It is essential that the correct system is utilised to ensure it can allow for thermal and floor movement. It is essential that care is taken when installing the grid to ensure the accuracy require to accommodate the relevant panel system. Accurately fitted grid will ensure a trouble free installation of the panels.

Want More Information?

For further information on our PSP Architectural systems you can go to our Downloads section where you will find a library of certificates and technical information or alternatively give our technical sales team a call on 01388 770490 to discuss your project.

Other PSP Architectural Systems:

Matrix SF

Matrix SF rainscreen system is available in a range of A1 & A2 fire rated materials and special features include pressings and louvers which can be manufactured to match to the panels. Panels can be manufactured in lengths up to six metres.

Matrix SFM

Matrix SFM is a CWCT tested rainscreen system based on Matrix SF but includes mullions for structural support. Panels are available in a range of materials such as Stainless Steel and are manufactured in lengths up to six metres.

Matrix SFC

Matrix SFC rainscreen system is made of pre-coated metal composite materials such as ACM, ZCM, CCM and is manufactured on our flatbed CNC machine offering high tolerances and sharp folds. Available in a range of finishes.

Matrix IP

Interlocking plank rainscreen system can be laid vertically or horizontally and are developed to provide a single skin panel at an economical price based on narrow face widths. Pressings and louvers can be the same material as the panels.